MORE THAN A MACHINE SHOP

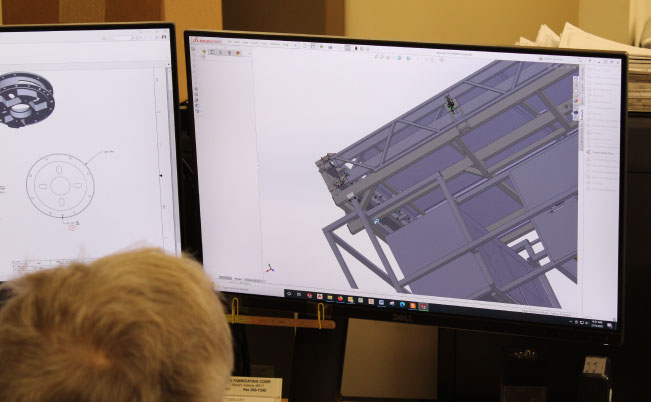

DESIGN & BUILD

Sometimes, what comes in the box does not solve the problem. Our ability to design and build custom machinery helps clients get what they truly need from their systems—efficiency, quality and productivity. We are not limited in our scope: our experience working alongside varied industry leaders allows us to adapt to your needs. Our exacting attention to detail, the fit, and finish of every component in each machine we build is provides you with innovative solutions, quality products and years of reliable service.

DESIGN & BUILD

Sometimes, what comes in the box does not solve the problem. Our ability to design and build custom machinery helps clients get what they truly need from their systems—efficiency, quality and productivity. We are not limited in our scope: our experience working alongside varied industry leaders allows us to adapt to your needs. Our exacting attention to detail, the fit, and finish of every component in each machine we build is provides you with innovative solutions, quality products and years of reliable service.

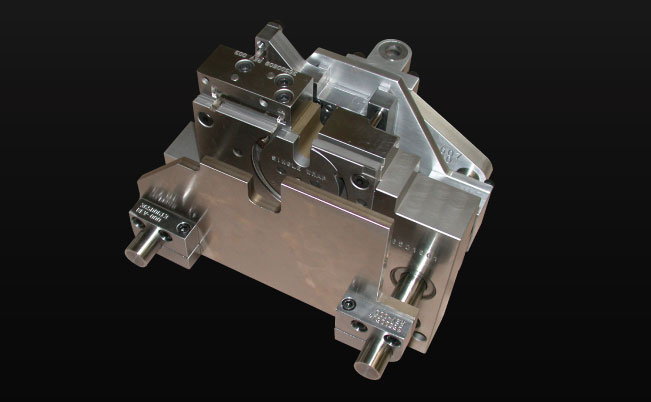

FIXTURES

WORKHOLDING

TOOLING

We conceptualize, design, and fabricate custom pieces of tooling, workholding, and fixtures specific to each of our client’s unique applications. Our state-of-the-art facility is fully equipped and ready to handle any challenge that comes through our doors—whether it’s a solution for holding, shaping or cutting parts. Workholding, jigs, tooling and fixtures are only as precise as the machinery and craftmanship they are built with, which is why we have invested in the machines and people necessary to get the job done.

FIXTURES

WORKHOLDING

TOOLING

We conceptualize, design, and fabricate custom pieces of tooling, workholding, and fixtures specific to each of our client’s unique applications. Our state-of-the-art facility is fully equipped and ready to handle any challenge that comes through our doors—whether it’s a solution for holding, shaping or cutting parts. Workholding, jigs, tooling and fixtures are only as precise as the machinery and craftmanship they are built with, which is why we have invested in the machines and people necessary to get the job done.

CONTROLS

MCTD designs, builds, and assembles machine controls for the custom machines we create and directly for customer use. No matter the industry or scope, we approach every control system project with the same relentless commitment to quality workmanship to achieve positive outcomes for the client. Our solutions include motion controls, assembly line automation, human machine interface, and more. Every control system we create adheres to NFPA and OSHA guidelines, so you can be sure that our control systems will meet your needs and exacting standards.

In late 2010, MCTD completed the acquisition of LaPorte, IN-based Quality Industrial Services (QIS). Like us, QIS specialized in designing and building process control and production line machinery for aerospace, healthcare, automotive, shipping, and manufacturing sectors as well and updating and repairing existing systems. We were very proud to welcome the QIS team into the MCTD family where their knowledge immediately made them an integral part of our organization.

CONTROLS

MCTD designs, builds, and assembles machine controls for the custom machines we create and directly for customer use. No matter the industry or scope, we approach every control system project with the same relentless commitment to quality workmanship to achieve positive outcomes for the client. Our solutions include motion controls, assembly line automation, human machine interface, and more. Every control system we create adheres to NFPA and OSHA guidelines, so you can be sure that our control systems will meet your needs and exacting standards.

In late 2010, MCTD completed the acquisition of LaPorte, IN-based Quality Industrial Services (QIS). Like us, QIS specialized in designing and building process control and production line machinery for aerospace, healthcare, automotive, shipping, and manufacturing sectors as well and updating and repairing existing systems. We were very proud to welcome the QIS team into the MCTD family where their knowledge immediately made them an integral part of our organization.

MACHINED PARTS

Machined parts are central to manufacturing businesses; and while most shops can produce parts as designed, we go the extra mile. Our engineering staff reviews all customer-supplied drawings prior to starting production; this optimizes efficiency, and ensures our customers get the product they need the first time. Our in-house design team uses state-of-the-art software, so every design—whether 2D or 3D—is fully detailed and presented to our customers. Whether it’s prototype work, on-demand emergency parts, or low-volume, high quality production jobs, MCTD’s team of master machinists are at your service.

MACHINED PARTS

Machined parts are central to manufacturing businesses; and while most shops can produce parts as designed, we go the extra mile. Our engineering staff reviews all customer-supplied drawings prior to starting production; this optimizes efficiency, and ensures our customers get the product they need the first time. Our in-house design team uses state-of-the-art software, so every design—whether 2D or 3D—is fully detailed and presented to our customers. Whether it’s prototype work, on-demand emergency parts, or low-volume, high quality production jobs, MCTD’s team of master machinists are at your service.

WIRE EDM MACHINING

MCTD is an exceptional provider of wire EDM services, delivering high-dimensional accuracy for tight-tolerance parts. We work with organizations of all sizes, in all industries to produce high-precision prototypes and tight-tolerance specialty parts using the latest EDM technology. For machine shops, OEMs and industry manufacturers in need of a manufacturing partner who can wire cut parts with precision, speed and quality MCTD is the perfect choice.

WIRE EDM MACHINING

MCTD is an exceptional provider of wire EDM services, delivering high-dimensional accuracy for tight-tolerance parts. We work with organizations of all sizes, in all industries to produce high-precision prototypes and tight-tolerance specialty parts using the latest EDM technology. For machine shops, OEMs and industry manufacturers in need of a manufacturing partner who can wire cut parts with precision, speed and quality MCTD is the perfect choice.

CMM INSPECTION

At MCTD, the responsibility for quality rests on the entire team. When time and money are invested in crucial parts and equipment, users expect trustworthy results. That is why we use a state-of-the-art CMM to verify critical dimensions or any specifications required by our customers. By measuring objects along multiple dimensions and points of contact, we ensure the parts and components in your project match the original design plans and are within tolerance.

CMM INSPECTION

At MCTD, the responsibility for quality rests on the entire team. When time and money are invested in crucial parts and equipment, users expect trustworthy results. That is why we use a state-of-the-art CMM to verify critical dimensions or any specifications required by our customers. By measuring objects along multiple dimensions and points of contact, we ensure the parts and components in your project match the original design plans and are within tolerance.

CONTACT US

Want to know more about MCTD and our custom-built services? Have a question about how we can meet your needs? Fill out the form below and a representative will follow-up with you.

EMPLOYMENT OPPORTUNITIES

Interested in joining our team? Do you have a skill that could help our organization grow? Do you like working on a variety of custom parts? If so, we want to hear from you! Feel free to apply below and let’s talk.