QUALITY INDUSTRIAL SERVICES

PROCESS CONTROLS

In manufacturing, process controls refers to the systems and software which control production processes. Such systems include process sensors, data processing equipment, actuators, networks connecting equipment, and algorithms to relate process variables to product attributes. Integrating process controls systems into your manufacturing organization allows for increased system throughput and enablement of automation, while removing the need to rework and/or scrap damaged parts. QIS process control solutions deliver consistent, high-quality performance our clients can depend on.

PROCESS CONTROLS

In manufacturing, process controls refers to the systems and software which control production processes. Such systems include process sensors, data processing equipment, actuators, networks connecting equipment, and algorithms to relate process variables to product attributes. Integrating process controls systems into your manufacturing organization allows for increased system throughput and enablement of automation, while removing the need to rework and/or scrap damaged parts. QIS process control solutions deliver consistent, high-quality performance our clients can depend on.

SYSTEMS INTEGRATIONS

Manufacting can be complex and the number of systems used to streamline and control processes is critical since manufacturers are becoming smarter by leveraging the latest innovations. When systems are integrated together, they provide a standard method for managing and reconciling data to accelerate and simplify the manufacturing processes. Our professional team of engineers can design and build state-of-the-art solutions for seamless systems integration for use in a wide range of applications.

SYSTEMS INTEGRATIONS

Manufacting can be complex and the number of systems used to streamline and control processes is critical since manufacturers are becoming smarter by leveraging the latest innovations. When systems are integrated together, they provide a standard method for managing and reconciling data to accelerate and simplify the manufacturing processes. Our professional team of engineers can design and build state-of-the-art solutions for seamless systems integration for use in a wide range of applications.

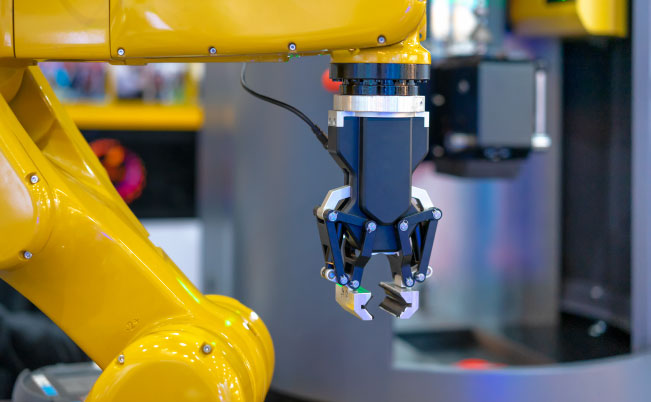

ROBOTICS

Robots are the present and future of manufacturing. This is because robotics and manufacturing are a natural partnership, with robots playing a key role in today’s manufacturing landscape. Automation maximizes efficiency and safety: manufacturing robots are used for high-volume, repetitive processes, especially where the speed, accuracy, and durability of a robot offers undeniable advantages—even working on a 24/7 basis. Robots also aid people in more difficult tasks such as lifting, holding, and moving heavy pieces. Whatever your need, we stand ready to design integrated or stand alone robotics systems to increase efficiency, reduce cost and improve safety.

ROBOTICS

Robots are the present and future of manufacturing. This is because robotics and manufacturing are a natural partnership, with robots playing a key role in today’s manufacturing landscape. Automation maximizes efficiency and safety: manufacturing robots are used for high-volume, repetitive processes, especially where the speed, accuracy, and durability of a robot offers undeniable advantages—even working on a 24/7 basis. Robots also aid people in more difficult tasks such as lifting, holding, and moving heavy pieces. Whatever your need, we stand ready to design integrated or stand alone robotics systems to increase efficiency, reduce cost and improve safety.

CONTACT US

Want to know more about MCTD and our custom-built services? Have a question about how we can meet your needs? Fill out the form below and a representative will follow-up with you.

EMPLOYMENT OPPORTUNITIES

Interested in joining our team? Do you have a skill that could help our organization grow? Do you like working on a variety of custom parts? If so, we want to hear from you! Feel free to apply below and let’s talk.